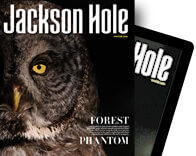

Read The

Current Issue

Hand-crafted Boards

Jackson Hole’s ski and snowboard makers carve their niches one turn at a time.

// By Rachel Walker // photography by NATALIE BEHRING

Like many, they came for the mountains and the snow. Come winter, they rose early to get the first tram and chased friends down secret stashes at the resort. They humped gear up Glory Bowl and toured into Grand Teton National Park. And as they threw themselves to the elements, they forged unique connections to this valley. How many people come to Jackson Hole and find their life plans upended as one season turns into another and into another?

Many, of course. But how many of those people manage to work for themselves building tools that ostensibly improve the lives of their powder-addicted brethren? Meet the custom ski and snowboard makers of Jackson Hole. These men—and, as of this writing, the founders/owners are all men—have engineering minds, woodworking skills, and an almost singular obsession with winter sports. They’re also part of a burgeoning field of small-batch board makers—custom craftsmen who consider themselves independent iconoclasts enchanted with the art and science of their chosen craft. “I have shaped an entire career and profession around two things that I love: skiing and building things with my hands,” says Michael Parris, owner of Igneous Skis. “I consider myself fortunate that I realized my priorities early on enough in my life to make them a reality.”

At our count, there are four area companies selling handcrafted boards: Igneous and Maiden in the town of Jackson, and Franco Snowshapes and Sego in Teton Valley on the west side of the Tetons. They’re all making a living doing what they love, each with unique visions about the types of boards they want to build. These builders bristle at the suggestion that they’re dudes who happened to luck into a métier. The companies grew out of ingenuity and curiosity, hard work, cultivating relationships, and a willingness to take risks. (And, yes, all four make a profit.) Together, the annual output of our four local ski and board makers improve winter for between 1,000 and 2,000 skiers and snowboarders.

Boutique ski and snowboard makers are nothing new. As long as there have been machines to sandwich together wood and metal, innovators have been building boards for a range of reasons: to experiment with flex and shape, to tailor equipment for specific conditions, to express themselves artistically, to simply see if they can. Some, like Igneous and Franco Snowshapes, create custom boards using specific customer measurements and other information about riding skill, preferred terrain, and athletic goals. Sego, by contrast, creates lines of skis that are all handmade but, for the most part, are not custom.

“A lot of the indie brands want to talk about how their materials or building process are superior to what mainstream brands build in factories, but that’s not the case,” says Jonathan Ellsworth, founder of BLISTER, a comprehensive, independent gear-review company based in Crested Butte, Colorado. “Where the indies blew up for absolutely great reasons was their shapes. That was game changing.”

“We wanted to make a ski that held up to the terrain and style of skiing that people do here—skiing over rocks, and jumping off cliffs, sometimes onto rocks. The durability Igneous is still known for today is a result of Jackson and the style of skiing we do here.”

—Mike Parris, owner of Igneous Skis

Ellsworth points to early independent ski brands like Line, founded in Seattle, Washington, in 1995, and 4Front, founded in Truckee, California, in 2002, as disruptors to the industry with innovations including fatter skis, rocker, and twin tips. “We went through a seismic change and now are in a spot where shapes of skis and the materials used—whether they come from an indie or an old European company—are more dialed in than they were ten years ago,” he says.

Where indie companies today really differ from traditional, mass-market ski and snowboard manufacturers is the buying experience and the brand story. Buying from indie companies differs drastically from going into a typical retail shop. At an indie, you’re likely going to talk with the actual ski builder when you go into the shop. There’s likely a bar or at least a beer fridge, and you’ll experience the company’s culture first-hand.

Ordering custom boards, like those made by Igneous, is even more intimate. You’ll be asked to answer a list of comprehensive questions designed to help the builder fine-tune the design specifically for you. These questions will include not just your height and weight but also your style of skiing and preferred type of snow and terrain. There’s an enhanced level of customer service, but this pales in comparison to the sense of community. Go to any town where there’s an independent board maker, and the local stoke around the brand is guaranteed to be high, which creates hype that appeals to people who want skis and snowboards built by hardcore riders and skiers themselves, says Nick Sargent, president of Snowsports Industries of America. “Each company is going to have their brand story, and that creates the buzz and notoriety,” he adds.

Naturally, where an indie ski brand is based is a big part of its story. That Jackson Hole can sustain one or two custom ski and snowboard companies is impressive. That four companies thrive here is unusual among ski towns. Unusual, but not unexpected, given Jackson Hole’s geography, community, and cachet.

The Teton Range is inimitable in its rigor and vertical relief, especially compared to other mountains in the Lower 48, and the snow that falls here is cold, dry powder. Jackson Hole Mountain Resort has been rated the best overall ski resort in North America a couple of times by different publications and is almost always rated as the best place for experts on the continent. There is backcountry skiing on Teton Pass and in Grand Teton National Park, and, if you’re willing to drive for an hour, on Togwotee Pass.

And then there’s the community, both on a micro and macro scale. We haven’t fact checked this, but it’s probable that, per capita, Jackson Hole is home to more world-class big mountain skiers and riders than any other place in the U.S. And then there are just the “regular” local skiers, many of whom think nothing of hucking themselves into Corbet’s, skiing the Grand Teton on a Wednesday morning, or taking a break from their morning commute to hike up and ski down Mt. Glory on Teton Pass.

“From the get-go, Igneous started because people here were devouring skis,” Parris says. “They were breaking two or three pairs a season. We wanted to make a ski that held up to the terrain and style of skiing that people do here—skiing over rocks, and jumping off cliffs, sometimes onto rocks. The durability Igneous is still known for today is a result of Jackson and the style of skiing we do here.”

The Jackson Hole community as a whole also helps these companies be successful. Each maker credits the local relationships they have for their longevity and continued existence. Any ski bum who’s lasted more than a season in Jackson Hole will tell you that the locals get by enormously on the relationships they forge. There’s a certain reciprocity. As friends become more established, more professional, the relationships lead to jobs, clients, housing, and more. It may sound transactional, but it’s not. It’s more like a mutual understanding and respect for what it takes to stick around and succeed in a place like Jackson Hole.

Finally there’s the “Jackson Hole” brand. “There is definitely a mystique about Jackson,” Parris says. “It has such a reputation, and the newish Epic and Ikon passes are bringing a lot of people here to check it out. This has actually helped—and challenged—us to broaden our offerings. Today we’re making skis for a lot of different types of skiers—it’s not just hardcore skiers, but also now skiers who appreciate having skis that are handmade locally and the craftsmanship versus mainstream skis.”

So what about the story of three of the four brands? (Maiden Skis was unavailable.)

Igneous

Michael Parris is the godfather ofJackson Hole ski building. He does what he wants—not in an entitled way, but in the vein of someone who has put in the years to perfect his craft and realize his vision. A skier since age four and the son of a carpenter, Parris grew up near Blue Knob, Pennsylvania, and learned to build things at a very young age. Driven by curiosity, he wanted to know how things worked. After high school, he studied architecture in college, not because he wanted to become an architect, but because he wanted to be able to design and build things. “I spent a lot of time thinking about how humans interact with their environment and objects and also about the objects we have and what they mean to us,” Parris says.

Parris paid his own way through college and dropped out at one point to earn money. He also traveled—to Chamonix, France, and then, in 1992 to Jackson, where he connected with his old friend Adam Sherman, who was just beginning to conceptualize the company that would become Igneous. The two experimented with materials and shapes, and then Parris returned to his studies. After graduating, he got a job working in robotics for NASA. A 1998 sabbatical brought him to Jackson for a summer of climbing, and he stopped in to see Sherman, who was about to build a new ski press. Sherman invited him to help. “It was fortuitous timing,” Parris says. It was also interesting enough to keep Parris in Jackson.

In 2000 Parris became Sherman’s business partner. In 2007, Parris bought Sherman out. Back then, custom skis were still something of a mystery. Early customers came to Igneous knowing they wanted something different from their stock skis but unable to articulate their desires. So, Parris began to ask questions. Why do you ski? What’s your favorite type of terrain? Out of the people you ski with, do they struggle to keep up with you or do you struggle to keep up with them?

“Learning to communicate with people has been the more challenging part of the process for me,” Parris says. “From the beginning, I understood the physics and the mechanics. But I need customers to tell me what they really want. So, it is on me to ask the questions to get them to tell me what they want.”

Sego Skis

In 2014, then-Victor, Idaho, mayor Zach Smith and Grand Targhee owner Geordie Gillett pitched brothers Tim and Peter Wells—one a long-time ski bum, the other a successful financial professional—about the benefits of moving to Teton Valley, Idaho. The Wells brothers had recently sold their Oregon-based custom ski company, Deviation, and were in the initial stages of building what would become Sego Skis. Ultimately, the pitch worked, and the two moved to Teton Valley and got to work.

Since its inception, Sego has steadily grown and has six models in its 2022/2023 lineup. The company’s skis have developed a reputation as hard-charging boards; Sego’s top athletes include Freeride World Tour Champion Isaac Freeland and up-and-coming Alta, Utah, skier Clare Chapman, among others.

The brothers make a formidable team. Peter, the company’s head production manager and designer, has worked in ski shops in Alta, Utah, and has climbed and skied all over the world. Having discovered his passion early, he said he was determined to be either a ski bum or work in the industry for the rest of his life. Sego allows for both. Sego CEO Tim Wells (pictured above) brings business acumen. After graduating from Cornell with a bachelor of science degree in statistics and business, he served as finance director for The Shelter Group, a real estate development and property management company.

Sego mainly sells direct to consumers from its factory and online, though its skis are available at Confluence Kayaks in Denver, Colorado, and in Australia at Blackbird Bespoke, a store that specializes in handmade and custom skis. Sego sold about 1,000 pairs of skis last season and aims to grow that by about 75 percent this season. And though they don’t make snowboards under the Sego name, they have the capacity to build snowboards and have made them for Elevated Surfcraft and Slideshow Snowboards.

Franco Snowshapes

Only after a season-ending injury sidelined him years ago did professional snowboarder Mikey Franco imagine a career beyond riding, guiding, and teaching. Franco sustained the injury in Japan, and during his recuperation, he met Taro Tomai, founder of the boutique Japanese ski brand Gentemstick. Enamored with the beautiful design of Tomai’s boards, Franco returned to Jackson Hole determined to create his own boards that honored the Gentem style of “snow surfing,” but with a uniquely American twist.

Make that a uniquely Franco twist. Franco wanted shiny, bold designs and, after learning the basics of how to make boards by hand, gravitated toward a lacquer finish. The clear, hard coating is similar to the finish on a nicely painted car and adds depth to the natural grains and colors on his boards. “It’s mouth-watering color, something you cannot get out of waxed wood,” (a more typical, classic finish), Franco says. “While wood is stunning, I wanted more. I wanted more longevity and eye-popping colors.”

Initially, snowboard making was a hobby for Franco. That fateful, injured winter led him to his childhood friend Mike Parris’s Igneous workshop in Jackson. Parris taught him the ropes. “When I had to miss an entire winter, I was devastated,” Franco says. “Mike bringing me in was just being a great friend and helping me get through that winter. But doing it definitely sparked something in me that I haven’t felt since I was a kid.”

Later, Kelvin Wu, of Maiden Skis, also took Franco under his wing. Franco credits Parris and Wu with mentoring him and helping hone his craft. But eventually he needed to strike out on his own. He wanted his own space with his own machines where he could push the boundaries of snowboard shape and design. Then some of Franco’s guiding clients offered to invest in his business. He found a plot of land in Victor, designed, and built his ideal factory space, and, in 2021, when construction was finished, signed a symbiotic tenant: Sego Skis.

Now that Franco Snowshapes has its own space, Franco can explore his creativity in new and different ways, creating snowboards that “totally blow other people’s minds,” he says. “I’m constantly asking myself, what are we doing with our brand versus what other folks do? How can we push it? What else can we do that people haven’t seen?” Recently, this resulted in a metallic board with aluminum sidewalls and top sheet. “No one has done that,” Franco says. “It’s insane and also totally functional.”

High-performance and high-art, each board Franco makes is tailored to the customer’s specifications, and each is unique. “The goal is to get into their head and build the board down from their head to their feet,” Franco says of the board-building process. “So long as they love it, it’s a success. I tell them that I don’t give a shit if no one likes your board but you. It was only made for you.” JH