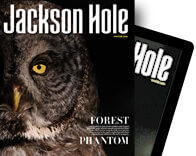

Read The

Current Issue

Foot Fetishists

Bootfitters want your feet to feel fabulous.

BY JEFF BURKE

Every ski town has its share of enviable jobs like ski patroller, heli guide, and night groomer. Then there are the revered jobs, demanding and performed by highly trained specialists who have honed their craft over decades, and who use their education and experience to help others.

To clients, these men and women are gods, stalwarts of science, smarts, and insight. Because of them, scores of skiers and snowboarders enjoy the slopes free from pain that otherwise might sideline them.

Are these gods knee surgeons? Massage therapists? Physical therapists? No. No. And no.

They’re bootfitters.

Easily the most important part of the skiing experience, boots are what connect skiers and riders to the slopes. Boots are also what cause them to enjoy—or hate—the experience. Bootfitting isn’t rocket science, nor is it witchcraft. It’s somewhere in between—a mix of art and anatomy that additionally requires knowledge of materials engineering and intimacy with the laws of resistance and pressure.

“That one was tricky,” says certified pedorthist (C.Ped) Matt Sheets, the head bootfitter at Teton Village Sports, about sizing a boot for a man missing three toes, including the big one. “But we got it.” Sheets has fitted Olympians, professional skiers, mountaineers, and movie stars. And he’ll fit you. Just make an appointment. Sheets’ bookings typically begin around the second week of October, and his schedule fills quickly. “Between December 20 and January 10,” says Sheets, “I’m booked solid—eight- to ten-hour days between fittings and working on boots.” A usual bootfitting session is one hour, though some can last more than three. “Those are the fun ones,” he says.

The day he was presented with the missing toes, the result of a catastrophic motorcycle crash, Sheets already had a packed schedule. But he couldn’t pass up the challenge. The skier missing the toes hadn’t enjoyed a run since his accident. It was no wonder: There was a large void in the boot’s toe box. “He walked in, showed and told me what was going on—his foot wouldn’t stay inside the boot—and asked if there was anything I could do to help,” Sheets says.

To fit the boot—it wasn’t as simple as putting him in a smaller one—Sheets crafted a serious insole and also a berm on the front of the missing toes. Then he added extra material to fill in the missing toe space. The berm buttressed the new coastline of his foot; the extra material not only took up space, but also helped keep the remaining digits warm. “That did it,” Sheets says. “He was then able to enjoy the rest of his ski vacation.”

Since arriving in 1990, Sheets left the valley for only three years (1995-98), during which he wrote and taught the curriculum for Colorado Mountain College’s advanced bootfitting clinic. Despite the time he has spent teaching others and all his education—to become a C.Ped, Sheets took 120-some credit hours at the University of Oklahoma, did one thousand hours of patient care, and passed a three-hour exam administered by The American Board for Certification in Orthotics, Prosthetics & Pedorthics—Sheets says bootfitting is mostly on-the-job experience. “School was a big eye-opener for anatomy,” he says. “But I’ve learned way more on the job than in any class.” (The state of Wyoming seems to agree; while Sheets and a couple of other valley bootfitters are licensed C.Peds, Wyoming doesn’t require that pedorthists be licensed. Fifteen states do, however.)

It’s not just people buying new boots that seek out Sheets and the valley’s other fitters. “Feet aren’t static,” Sheets says. “They can and do change.” Sheets says 95 percent of women who have had a baby see changes in their feet. “I’ll have to redo the insoles of the majority of those,” he says. “Men typically don’t change as much. I had a guy come into the store that I did insoles for seven years ago and everything looked exactly the same. In a man’s case, it is most often an injury that causes their feet to change.”

Boots and liners do wear and change over time. “I give boots about 150 to 200 days before there is noticeable wear and tear,” Sheets says. “At that point, the boots are ready to be replaced or shimmed up or padded to re-create the same tight fit they had at the beginning.” While Sheets says boots, with the proper maintenance, can be good for years, he does have clients who come in for a new pair every season. “Sometimes they just want the latest and greatest; other times they want that secure, tight fit that comes with a brand-new boot.”

There’s no typical day for a bootfitter. Sometimes they decide a custom footbed is the solution for a skier with high arches. Or they must make space in a boot for pronounced anklebones or to accommodate a bunion (that itself may be the result of years of abuse by ill-fitting boots). They might get a client missing most of his toes. Or a world champion freeskier walks in after painful boots forced her to walk out of Granite Canyon.

“I had my boots done years ago by a fitter,” says Jess McMillan, a Jackson Hole native and the 2007 International Freeskiers & Snowboarders Association (IFSA) World Tour Champion. “And then I had to take them off halfway up Granite Canyon and walk out in my socks.” A former ski racer, McMillan is familiar with boot discomfort. “I know what uncomfortable feels like, and these were unbearable,” she says. She went to Matt Haviland, the chief bootfitter and also shop manager at Hoback Sports.

Haviland grew up skiing and biking around Portland, Oregon. He moved to Jackson in the winter of 1998-99 to “ski as much as possible,” he says. Haviland started as a rental tech, “but I found bootfitting much more rewarding by being able to make people better at skiing and increase their love of it,” he says. Haviland attended MasterFit University, a training center offering bootfitting courses, clinics, and continuing education at physical campuses around the world and also online. When McMillan walked in, he had ideas to make things better. Haviland started by rebuilding her footbeds and then took a close look at her liners. “He was a miracle worker,” says McMillan. “They were comfortable as a slipper, and still performed.”

If you’re lucky, you’ll meet a bootfitter before you need him. “A good fitter’s job is to take a look at the foot and say, ‘Here’s the right boot, and now let’s size accordingly,’ ” says Ryan “Bootsie” Huggins, a C.Ped at Pepi Stiegler Sports in Teton Village. The characteristics of ski boots themselves vary radically. Boot companies and models use different lasts, lengths, widths at the metatarsal heads, and volume. Some boot companies are known for wide lasts (Head, for example). Others offer certain models in two widths (Rossignol, Lange, Atomic).

Bootfitters need to know all of this to pair a boot to an individual’s foot. “A fitter will do their best to put you comfortably in a brand they sell,” says McMillan, “but if it’s simply not to be, they’ll send you to a worthy competitor. A really good fitter has your best interest at heart.”

There’s also personal experience: “Many wide-lasted boots tend to be soft,” says Huggins. “Head is one of the best wide-lasted brands that is still very stiff.”

Although only bootfitting in this valley for six years, Huggins began tinkering with boots when just a teenager. He first worked in a small shop in the Salt Lake City area putting shims and wedges into boots, which he got very good at. He developed a reputation as the go-to guy for difficult fits. Co-workers nicknamed him “Bootsie” for his problem-solving prowess. Intrigued by the challenge of bootfitting, Huggins traded in a soccer scholarship for the University of Oklahoma’s pedorthist program. Today, Huggins, uh, Bootsie—it’s rare to find a skier in this valley who knows him as anything but that—has more than twenty years of bootfitting experience, a cult-like following, and 1,200-plus hours of research into arch mechanics done at the University of Utah. These guys truly are highly trained and passionate about their craft.

Good bootfitters share two qualities: a preternatural attention to detail and a mechanical mindset. They zero in on the type of feet clients have and problem-solve to build a comfortable boot fit around that. “Their foot shows me what to do with the boot,” Haviland says. Fitters use grinders, stretchers, and tools such as the “Scott Press,” a steel post with a rounded knob and lever arm. The Scott Press, which looks like an instrument of torture, allows fitters to round out heel pockets and punch out areas that might rub anklebones, among other customizing tasks. If a fitter can imagine it, a Scott Press is most likely the tool that can do it.

Great bootfitters must adapt as well. “Today, there isn’t a boot on our wall that doesn’t have a custom moldable liner,” Sheets says. “All of our Salomon boots have custom moldable shells. It is incredible what you can do with these boots. Years ago, we’d be punching boots out to accommodate bunions. Now we’re doing that right at the beginning with moldable materials.”

These advances in boot technology don’t just affect fitters. “We get someone with a EEE foot,” Sheets says, “and I put them in a Salomon boot with a moldable shell and liner, and they have the most custom boots ever made. Getting people set up so they can ski all day instead of kicking their boots off at lunch, giving up, and heading to the Moose for a beer—that’s what makes me happy.”